Metal Casting

Forging Excellence, Welding Innovation: Your Trusted Source for Welding Auxiliary Equipment!

- E-mail :eric@weldc.com

- WA:+86-15006193977

Description

Our offerings encompass a diverse range of metal casting processes, embracing die casting, gravity casting, precision casting, sand casting, low-pressure casting, investment casting, and non-ferrous casting. Employing materials such as aluminum, aluminum alloy, zinc, brass, bronze, copper alloy, iron, steel, and stainless steel, we adhere to technical standards like ASTM, ANSI, SAE, DIN, and BS in material selection. This commitment ensures the precision and quality synonymous with our professional metal casting services.

Property

1. In the realm of metal casting, the process takes on various forms, with die casting and gravity casting emerging as the most prevalent methods.

2. Die casting yields metal parts renowned for their durability, high dimensional stability, and exceptional heat resistance, all while maintaining stringent tolerances.

3. Gravity casting, a subtype of permanent mold casting, offers advantages such as reusable molds, superior surface finish, precise dimensional accuracy, and elevated production rates.

4. The metal casting process involves the high-temperature melting of metals, followed by the utilization of molds to give shape to molten metal, resulting in the creation of new items.

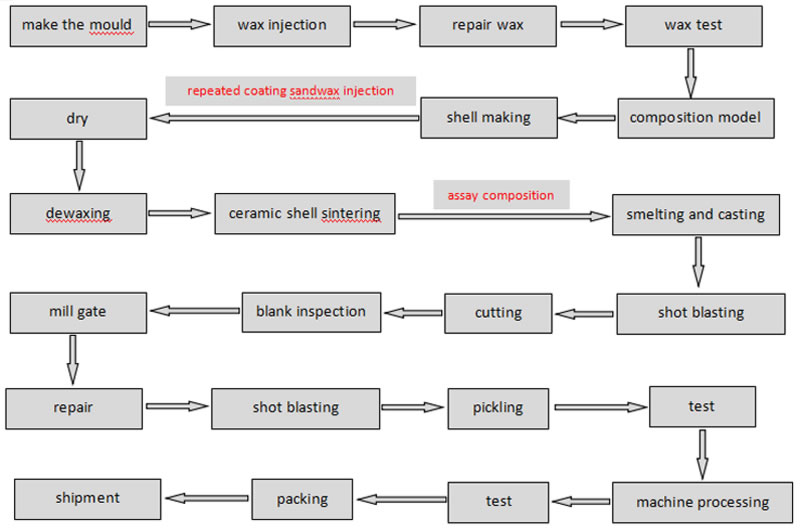

Casting Process Flow Chart

Metal Casting Machine Process

| Die Casting | Gravity Casting | Precision Casting | Sand Casting |

|

|

|

|

| Low Pressure Casting | Investment Casting | Non ferrous Casting | |

|

|

|

Materials of Metal Casting

| 1.Aluminum Casting | 2.Zinc Casting | 3.Brass Casting | 4.Bronze Casting |

|

|

|

|

| 5.Magnesium Casting | 6.Stainless Steel Casting | 7.Carbon Steel Casting | 8.Iron Casting |

|

|

|

|

Our comprehensive range of services includes:

1. Heat Treatment: Offering processes such as Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization to enhance material properties.

2. Machining: Providing precision machining solutions encompassing Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, and Riveting.

3. Surface Treatment: Employing advanced techniques such as Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis, and Passivation for superior surface finishes.

4. Assembly: Meticulous assembly services incorporating Studs, Steel Sall & Helicoil Inserts, O-rings, and Gaskets to ensure the seamless integration of components.

5. Packing: Ensuring secure and professional packaging for the safe transit of products.

6. Testing Report, Quality Control Report: Providing detailed reports to affirm our commitment to precision and quality control, ensuring products meet the highest industry standards.