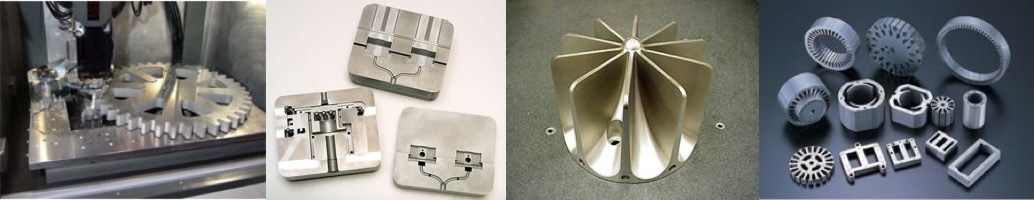

CNC Machining

Forging Excellence, Welding Innovation: Your Trusted Source for Welding Auxiliary Equipment!

- E-mail :eric@weldc.com

- WA:+86-15006193977

Description

CNC machining exemplifies a deductive manufacturing process where automated cutting tools meticulously eliminate material from either a raw block or an existing part. This precision-driven method, governed by computer numerical control, is adept at working with an array of materials, including but not limited to steel, stainless steel, aluminum (alloy), brass, bronze, copper alloy, magnesium (alloy), titanium (alloy), showcasing its versatility across various industries.

Advantages

1. Leveraging our substantial capacity, we deliver CNC machining parts with unparalleled efficiency, upheld by seasoned engineers employing cutting-edge software and equipment.

2. Tailored for prototypes, production parts, repeat-use master patterns, and diverse applications demanding precision.

3. Craft components from a versatile range of materials, sourced from our inventory or specially ordered to meet your project requirements.

Classification of Computer Numerical Control Machining

We offer an economical yet precise CNC machining solution tailored to customer requirements, encompassing a comprehensive array of services: CNC turning, CNC boring, CNC drilling, CNC milling, CNC grinding, CNC cutting, CNC laser engraving, CNC laser marking, and CNC EDM machining.

CNC turning Service

CNC boring Service

CNC drilling Service(CNC Reaming Service)

CNC milling Service

CNC grinding Service

CNC cutting Service (CNC Plasma Cutting, CNC Laser Cutting, CNC Waterjet Cutting)

CNC laser engraving Service(CNC laser marking Service)

CNC EDM machining Service(Wire EDM Machining, Sinker EDM Machining, Small Hole EDM Drilling)

As a distinguished CNC machining supplier in China, we present a dependable and cost-effective computer numerical control machining solution. Our comprehensive services include:

1. Plastic Molding, Metal Casting, Metal Forging, Sheet Metal Fabrication, Welding Fabrication, Rolling/Bending/Roll Forming Service

2. Heat Treatment: Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization

3. Surface Treatment: Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis, and Passivation

4. Assembly: Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

5. Packing

6. Testing Report, Quality Control Report

Our commitment to professionalism and precision ensures a seamless and reliable CNC machining experience for our valued clientele.