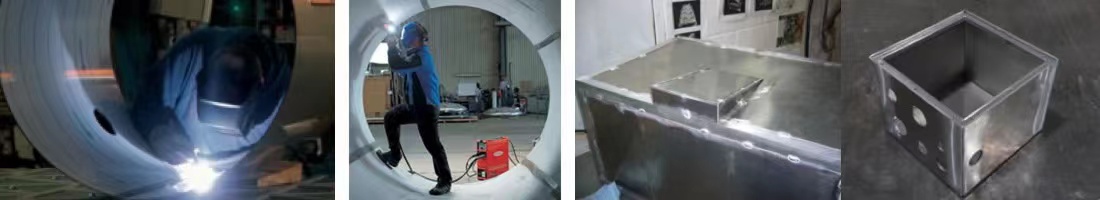

Metal Welding

Forging Excellence, Welding Innovation: Your Trusted Source for Welding Auxiliary Equipment!

- E-mail :eric@weldc.com

- WA:+86-15006193977

Description

Metal welding, or welding fabrication, is a refined method aimed at fusing metals through the strategic application of heat. Unlike low-temperature methods, such as brazing, our approach involves introducing filler material to create a molten pool.

This pool undergoes controlled cooling, resulting in joints with strength comparable to the base material. Our professional approach emphasizes precise heat application, often complemented by pressure, ensuring welds meet high standards of strength and durability.

Advantages

1. We provide a versatile and cost-effective metal welding fabrication solution, covering a wide range of techniques including submerged arc welding (SAW), metal inert gas welding (MIG), tungsten inert gas welding (TIG), spot welding, laser welding, and robot welding.

2. Our commitment to excellence is reflected in a comprehensive suite of services, offering suitable materials, cost-effectiveness, unwavering quality, detailed test reports, and reliable delivery timelines.

3. With an extensive selection of metal welding materials, including steel, stainless steel, aluminum alloys, brass, bronze, copper alloys, magnesium alloys, titanium alloys, and various others, we showcase our ability to meet diverse project requirements with professionalism and precision.

Classification of Welding Fabrication

SAW Welding (SAW welding)

Description:The submerged arc welding process is an innovative technique known for its superior quality, heightened efficiency, and minimal energy consumption. This advanced methodology exemplifies our dedication to providing high-caliber welding solutions and upholding professional excellence.

Advantage:

1. Renowned for its stability in welding quality, heightened productivity, and minimal occurrence of arcs and smoke, our welding process underscores our unwavering commitment to superior craftsmanship and adherence to professional standards.

2. Positioned as the preferred choice for pressure vessel and pipe manufacturing, this exceptional welding technique reflects our dedication to delivering optimal solutions for critical industrial applications.

3. Our welding methodology seamlessly extends to the fabrication of box beams and steel structures, demonstrating our proficiency in providing precise and reliable welding solutions tailored to diverse structural requirements.

Metal Inert Gas Welding (MIG welding)

Description:Utilized for the active welding of various metals and alloys, including aluminum, magnesium, magnesium alloy, and aluminum alloy, this technique showcases our commitment to delivering precise and high-quality welding solutions across a spectrum of materials, emphasizing our dedication to professionalism and excellence.

Advantage:

1. Ensuring the stability of the welding arc is paramount to our methodology, a testament to our dedication to precision and operational excellence.

2. Our welding process guarantees uniform and aesthetically pleasing weld formations, underscoring our commitment to delivering outcomes that meet the highest standards of quality and craftsmanship.

3. Implementation of our techniques not only enhances the overall welding process but also significantly augments welding efficiency, showcasing our unwavering dedication to professional advancement and superior performance.

Tungsten Inert Gas Welding (TIG welding)

Description: Tungsten Inert Gas (TIG) welding is extensively applied in non-ferrous metal welding, including aluminum, magnesium alloys, stainless steel, high-temperature alloys, titanium, and titanium alloys. Our expertise in TIG welding extends to materials prone to oxidation, active metals, and refractory metals such as molybdenum, niobium, and zirconium. This proficiency also includes ordinary carbon steel, low alloy steel, and other commonly encountered materials, showcasing our commitment to professional excellence and versatile welding solutions across diverse materials and applications.

Advantage:

1. Our welding process excels in joining non-ferrous metals, stainless steel, and alloys susceptible to oxidation and chemical activity, showcasing our commitment to precision and professionalism.

2. Tailored for precision welding, our methodology is adept at ultra-thin sheets and plate materials, reflecting our commitment to superior solutions across diverse materials and thicknesses.

Spot Welding

Description:Spot welding excels in thin plate fabrication, eliminating the need for airtight joint laps and suitable for materials below 3mm thickness, often achieved through stamping and rolling. This method creates individual points of contact on welding joints, requiring superior metal plasticity. Our professional spot welding approach emphasizes precision, ensuring high-quality welds that meet the specific demands of thin plate manufacturing.

Advantage:

Spot welding is an efficient and cost-effective method for establishing connections at high speeds. This technique reflects our commitment to economic viability and operational expediency, showcasing our dedication to delivering professional solutions that prioritize both speed and cost-effectiveness in welding processes.

Laser Welding

Description: Laser welding is an advanced precision method utilizing a high-energy-density laser beam as its heat source. Positioned as a crucial application in laser material processing technology, it exemplifies our commitment to cutting-edge methodologies, achieving unparalleled precision. This sophisticated technique underscores our dedication to professionalism and the integration of state-of-the-art technologies in delivering superior welding solutions.

Advantage:

1. The laser beam’s precise focus in a confined area allows for the welding of small and intricate components with remarkable precision.

2. Laser welding excels in joining metals with differing physical properties, showcasing its versatility across a spectrum of materials.

3. Proficient in welding dissimilar materials, the technology seamlessly engages various heterogeneous materials.

4. Laser welding’s automatic high-speed capabilities, coupled with digital or computerized control, underscore our commitment to professional and technologically advanced welding solutions.

Robot Welding

Description: The welding robot is utilized for a broad spectrum of tasks, including welding, cutting, and spraying operations. To accommodate diverse applications, the robot features a shaft mechanical interface, commonly presented as a connection flange. This design allows for the smooth integration of various tools or end effectors, emphasizing our commitment to versatility and professionalism in meeting complex welding needs.

Advantage:

1. Enhance and stabilize welding quality with advanced technological interventions.

2. Boost labor productivity through the incorporation of efficient and precise welding methodologies.

3. Reduce technical skill requirements for operators, simplifying the operational process.

4. Expedite product cycles, showcasing our commitment to streamlined and time-efficient manufacturing practices.

As a prominent welding fabrication supplier based in China, we specialize in delivering high-quality and cost-effective metal welding solutions. Our comprehensive services include:

1. Cutting Services:

– Sheet Metal Shearing

– CNC Saw Cut

– CNC Torch and Plasma Cut

– CNC Laser Cut

– CNC Waterjet Cut

2. Rolling/Bending/Roll Forming Services:

– Sheet, Plate, Tube, Pipe

– Bar, H/I/L/T Beam, Channel/Angle/Section Steel

– Structural Steel

3. Heat Treatment Services:

– Hardening

– Annealing

– Normalizing

– Stress Relieving

– Softening

– Graphitization

4. Machining Services:

– Turning

– Boring

– Drilling

– Milling

– Threading

– Grinding

– Cutting

– Engraving

– EDM Machining

– Riveting

5. Surface Treatment Services:

– Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing)

– Shot Blasting

– Sandblasting

– Spray Painting

– Powder Coating

– Thermal Spraying

– Anodizing

– Chrome Plating

– Nickel Electroplating / Electroless Nickel Plating

– Hot-Dip Galvanizing

– Copper Plating

– Phosphorizing

– Electrophoresis

– Passivation

6. Assembly Services:

– Stud

– Steel Sall & Helicoil Inserts

– O-ring

– Gasket

7. Packing Services:

– Ensuring secure and professional packaging for your products.

8.Testing and Quality Control Reports:

– Providing comprehensive testing reports and quality control documentation to ensure the highest standards are met.

Our commitment to professionalism is reflected in the diverse and meticulous range of services we offer, ensuring that each project receives tailored solutions meeting the most stringent quality and precision requirements.