Welding Manipulator

Forging Excellence, Welding Innovation: Your Trusted Source for Welding Auxiliary Equipment!

- E-mail :eric@weldc.com

- WA:+86-15006193977

Description

This welding manipulator, also called column boom manipulator, is mainly installed with the TIG and MIG welding machine. And we can provide you with three types of welding manipulators for our clients: radial-position, fixed, and fixed rotating manipulators.

It is mainly used to offer firm support for high-precise welding, and can be also used for welding vessels, wind towers, pipelines, and many other polishing machines.

It is mainly composed of a column, a boom, a guide holder, and a trolley.

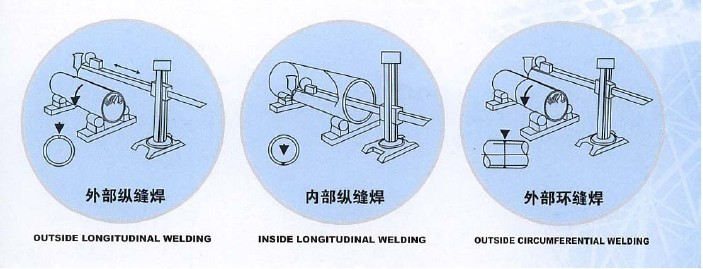

This column boom manipulator can reach both of the inside of small internal diameters and the outside of big diameters in order to weld circumferential joints as well as longitudinal joints.

Furthermore, we can attach more functions to this welding manipulator, such as tracing, monitoring, and solder recycling function. And we can also design and manufacture welding manipulators in accordance with specific demands of our clients.

1) The operation machine is used for flat welding, butt welding seam and internal and external longitudinal welding seam of cylindrical body and it can be fitted with roller stand for welding seam of internal and external circular welding seam. If it is fitted with positioner, different type of body can be made for different places of welding.

2) Main body box type welding structure is treating by stress after welding and fine machining shall be made. The guide surface adopts precision grinding processing or ensure the sophistication and smooth running.The precision grinding rack is installed on crossbeam to guarantee its flexibleness and free expansion and contraction.

3) The crossbeam’s expansion and contraction, motor-driven turning of column and running of motor-driven trolley adopt AC frequency control of motor speed and the constant torque output the stat and the stop are very rapid.

4) The raise and lifting of crossbeam adopt the constant speed type, thus its lifting is smooth, safe and reliable.

5) The Base have the fixed type, fixed and rotation and movable and rotation.

6) There are linkages interface, which can realize linkage synchronization with welding turntable, welding positioner.

7) Anti-drop is with self-lock principle, it can stop any sudden drop, anti-drop ingenious, shockless and reassuring.

8) LH shape Heavy duty machine is fitted with operation platform, which is easy for operation and regulation.

9) The manual control box may realize the remote control.

10) Cross-tuning system with motorized slide can realize welding torch in three-dimensional adjust, which satisfy welding torch adjust for welding longitudinal and circular seam, 200mm adjust range can make the easy operation.

11) There are limited switches for extension, lifting and rotation. Make sure the safety operation. At the same time mount overloading, over current, under voltage and short circuit for the whole system control.

12) Safety device can guarantee the basement move on the rail stable.

13) Control panel as the picture show. That could control the welding manipulator, LINCOLN welding machine, welding rotator, all will be integrated.

Features of Welding Manipulator:

1. Both of the column and the boom adopt a V-type rail, and possess high loading capacity.

2. To make the positioning of the boom stable and smooth, the column is equipped with a brake motor.

3. The guide holder has a safety pin, and the column has a row of security holes. The safety pin will enter into a security hole when the chain breaks down. In this way, serious accidents are successfully avoided.

4. A pivoting support is used to connect the lower part of this manipulator with its foundation, thus smooth and stable rotation is obtained. Besides, it can also facilitate the work of welding many workpieces at the same time.

5. The guide holder connects the boom with the column, thus making the vertical adjustment and horizontal extension possible.

6. The boom is also equipped with a cross electrical regulator.

7. A stepless speed regulating converter, with stable and reliable performance, is used to control the extension of the boom. And the converter has a failure testing mechanism, which will give an alarm when something wrong happens.

8. The guide holder is box-shaped. And its upper part is connected with the lifting chain; its rear part is linked with the column through the chain wheel; and its front part is connected to the boom.

9. Its speed reducer is mainly composed of a professional cucloidal-pin wheel and a worm-gear speed reducer.

10. This column boom manipulator adopts a total-sealing oil immersion lubricating mode to help keep off dust, slag, and many other impurities.

Technical Parameters of Welding Manipulator (Column Boom Manipulator):

Accessories of Welding Manipulator:

To better facilitate our clients’ operation, we provide several accessories for your choice, such as flux recovery and transmitting machine, racking system, moniter, and more.

Summary:

Our LH series welding manipulator is a cornerstone in automated welding systems, seamlessly integrating with welding turning rolls, automatic welding machines, and advanced welding control systems. Its versatility makes it indispensable across a range of industries including boiler manufacturing, pressure vessel fabrication, chemical processing, petroleum refining, metallurgy, construction, and machinery production.

Designed to excel in both inner and outer longitudinal welding, as well as circumferential welding of various seams on cylindrical workpieces, the LH series stands out for its advanced structural design and comprehensive functionality. Its intuitive operation ensures ease of use while contributing to improved welding quality and efficiency.

To accommodate diverse operational requirements, the manipulator offers flexible configurations, including fixed, fixed with rotation, and movable with rotation options. This adaptability ensures that it can be tailored to meet the specific needs of any production environment.

Working condition:

Surrounding condition

a) Height above sea level: Below 1000m

b) Ambient condition:-5℃~40℃

c) Ambient Operating Conditions:Date average temperature≤25℃,Relative humidity in max humid month≤90%

d) Voltage fluctuate:±10%(Frequency is rating value)

e) Frequency fluctuate:≤±1%(Voltage is rating value)

Structure Instruction:

Our welding operation frame boasts a robust rectangular girder column design, featuring a double rectangle orbit style. The top of the column houses the elevating system for the cross-beam, driven by a motor coupled with a worm wheel and chain sprocket wheel mechanism. Ensuring stability, an oriented structure is positioned on one side of the chain, while balance iron within the column maintains equilibrium for the cross-beam. Anchored securely to the ground with anchor bolts, the bottom of the column provides a stable foundation.

The cross-beam’s traversal is powered by an AC motor and worm reducer, which in turn drive the gear and rack coupling. Welding speed is adjustable within a specific range for optimal performance. To facilitate operation, a remote box is connected to the control box. The telescopic function of the cross-beam is controlled by frequency conversion, ensuring high precision and accuracy in positioning.

The oriented structure serves as the connection point between the column and the cross-beam. Eight eccentrically adjustable oriented wheels are mounted on the oriented structure, allowing for easy adjustment of the spacing between the column and the beam. Additionally, the AC motor and worm reducer are mounted on the oriented structure to streamline operations.

Safety is paramount, with a ratchet wheel integrated into the oriented base to prevent arm falling in the event of external impact accidents. This feature provides added protection, with ratcheting spines guiding blocks and arms, securing them in place within the columns.

The trolley, essential for mobility, comprises a traveler swing bearing and lock frame. Powered by a pair of cycloidal pinwheel reducers and motors, the trolley moves along wheels, while column rotation is facilitated by another motor. A lock structure on the rotation mechanism ensures stability during welding operations. Additionally, a grapnel between the trolley and rails enhances safety during use.

Furthermore, we include a staircase as a supplementary installation, facilitating user access for maintenance and overhaul tasks.

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of adjustable welding rotator in China. And we can also provide our clients around the world with many other products including special welding rotator, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service. Our products have been well received by customers from many countries, such as Spain, India, Germany, South Africa, Brazil, Chile, Argentina, Russia, Italy, France, Vietnam, and more. If you’re interested in our adjustable welding rotator, please don’t hesitate to contact us whenever you want.